Call or Text 716-697-3560 Today!

Carrigan Painting's

Materials & Methods

We’ve spent over 15 years refining not just our techniques, but the materials we trust in your home. We’re not brand loyal. We select the best products available locally based on performance, not marketing. From Behr and Benjamin Moore to Sherwin Williams, USG, Larsen, PPG and others, every product we use is handpicked for how it performs in real world conditions, not just on a sales sheet.

Jump to a section:

Paint >

-

Behr Dynasty –

Product Link

| We use this for Interior & Exterior painting.

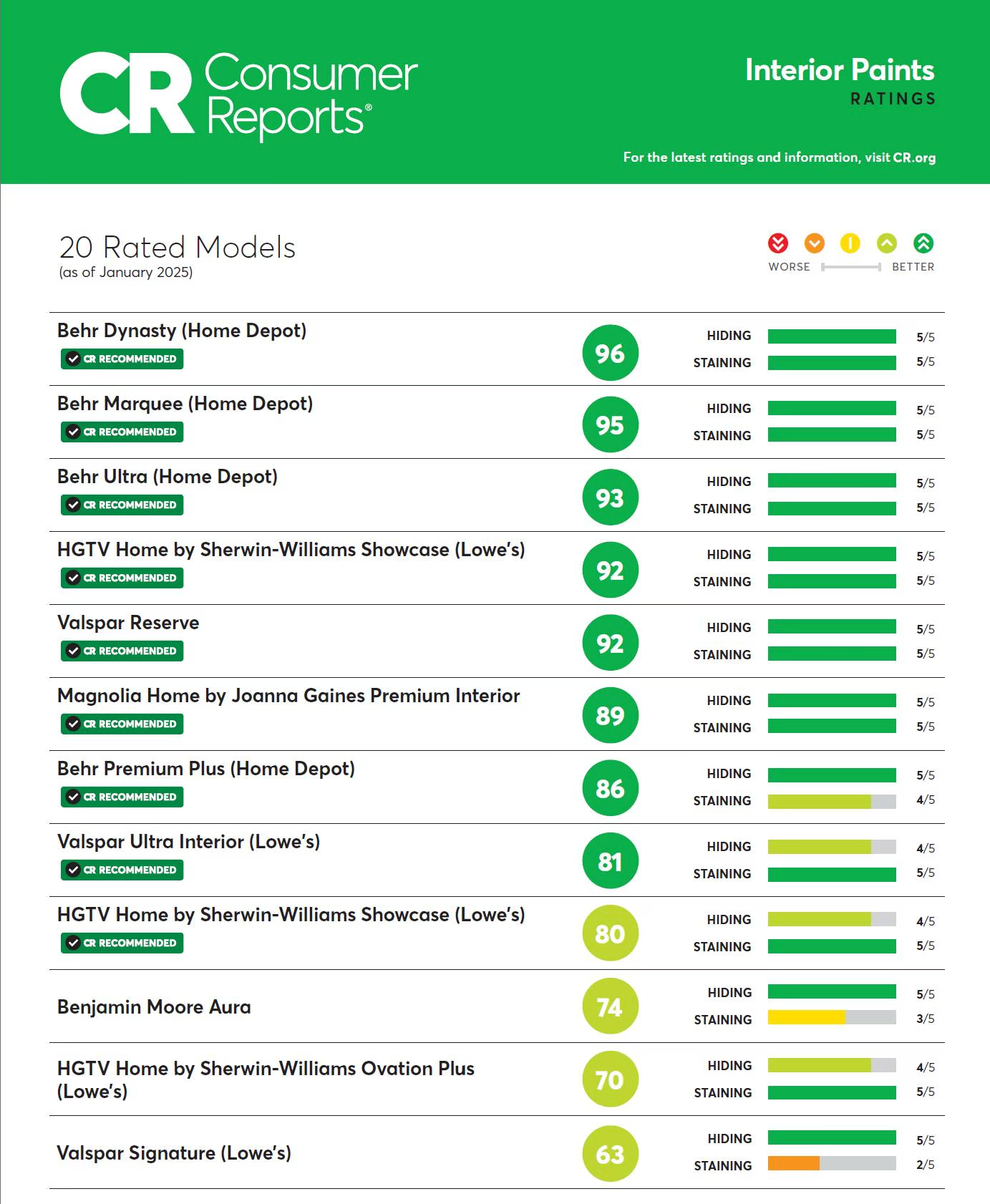

Our go-to for people who want top quality paint and excellent coverage. Behr Dynasty has slightly better coverage than Behr Marquee but with out the stickness. It’s Behr’s flagship line, and in our experience, the best-performing interior and exterior paint readily available in Western New York. We actually prefer it over Benjamin Moore Aura, and as a bonus, it's about 30% less expensive. In a year where homeowners are more price-conscious than ever, Dynasty delivers premium results without the premium markup. Behr Dynasty Exterior is available in Clarence, West Seneca, Lockport stores.

Consumer rating: 4.5 with 2,300 reviews

Comparable to: Benjamin Moore Aura, Behr MarqueeBehr Marquee isn’t a bad paint, especially for DIYers. It dries fast and covers well, which is great if you’re painting a bedroom on a Sunday afternoon. But for professional painters, its very sticky and dries too fast. By the time we’re ready to roll, the cut-in has already begun to set. That causes serious problems: when we roll into the cut-in, it grabs the setting paint, creating ugly stipple and roller drag.

At that point, the fix is labor-intensive: sanding, patching, priming, and repainting. Or waiting 60-90+ minutes for it to dry, which can lead to “picture framing” and "ghosting" (visible edge lines that flash under lighting). Either way, it’s not worth it. Dynasty gives us better coverage with better workability and fewer problems. -

Behr Scuff Defense –

Product Link

Used for most interior wall applications. Excellent coverage and durability. Great for hallways, kitchens, kids room, and other high traffic areas. We haven't used a product like it. You can rub up against a wall painted with Behr ScuffDefense, and not leave a mark. Its pretty amazing stuff.

Consumer rating: 4.6 with 9,300 reviews.

Comparable to: Benjamin Moore Scuff-X -

Behr Cabinet, Door & Trim Enamel –

Product Link

This is our go-to product for doors and trim. It’s a self-leveling, high-hide enamel that cures to a hard, durable finish—resisting chips, scratches, and everyday wear better than many premium-name alternatives. Suitable for both brush and spray applications, it performs reliably in real-world conditions. Also available in oil-based quarts for specialty use.

Consumer rating: 4.3 with 2,800 reviews.

Comparable to: Benjamin Moore ADVANCE — but with a more forgiving application and a much faster turn around time. ADVANCE has a 7-14 day cure time - meaning it can be easily damaged during this time. -

Benjamin Moore –

We have nothing against Benjamin Moore, except that its local availability can be problematic for us, and its typically more expensive to comparable alternatives. But local availability is the biggest factor for us. There are two Ben Moore stores in WNY, and some ACE Hardware stores and Ed Youngs in the Village of Williamsville carries a limited selection.

-

PPG –

PPG has the same problem as Ben Moore. PPG has two? Maybe three stores in WNY. One on Transit Road in East Amherst, and the other by Rt. 400 on Union Road in West Seneca. The PPG at Home Depot is a different product than what PPG sells at their stores. Due to this limited availabity, we have limited experience with their products. -

Sherwin Williams –

While Sherwin Williams stores are plenty, their residental archetectural paints have suffered tremendously since 2021. Sherwin decided to bring their titanium dioxide manufactuering "in house" to secure their supply chain. When they did that, they had to tweak all their formulas for this change. Unfortunately they tanked their products in the process. Then lied about it for two years. (Corporate not retail). Very unfortunate too since the people that work at Sherwin Williams are among the hardest working, best people you will ever work with from a material supplier. We ultimately switched to Behr mid-job in fall 2022. Read why on our blog (opens in new tab). - Vinyl paint is the cheapest. It’s common in builder-grade or discount brands. It doesn’t stick well and tends to crack on plaster or older drywall. Also doesnt hold up well outside.

- Latex paint just means it’s water-based. Some latex paints are okay, but it depends on the resin — often it’s a blend of vinyl and acrylic.

- 100% acrylic paint is the good stuff. It’s flexible, breathable, and bonds properly to old plaster, wood trim, ceilings, and even problem surfaces. That’s what we use.

-

Sherwin Williams Problock HS Oil –

Product Link

Our go-to interior primer. This solvent-based, high-solids formula dries in under 30 minutes and then odor is gone. We use it to spot prime water stains, seal bare wood, and prime lime based plaster patches. It also performs well when converting older oil-based trim or doors to acrylic finishes.

We continue to use this product extensively due to our specialization in traditional plaster repair. We’ve tested New York VOC-compliant alternatives, they cost more, smell worse, and take far longer to dry. This one simply works better for our needs.

Comparable to: None. -

Sherwin-Williams Extreme Block Interior & Exterior Alkyd Primer –

Product Link

Our preferred exterior primer for bare wood. Unlike latex or acrylic primers, this alkyd primer penetrates the surface instead of just laying on top, which provides superior adhesion. It’s more expensive than latex primers, but it performs significantly better, especially when prepping weathered wood surfaces for painting. It also helps prevent tannin and stain bleed-through when applying high quality exterior topcoats.

Comparable to: None. -

Zinsser B-I-N Shellac based Interior Primer –

Product Link

Our alternative for people who are sensitive to oil-based primers. BIN has excellent stain-blocking properties and dries very quickly. We use it sparingly due to the strong odor during application. Think aerosolized vodka. (No, it’s not pleasant.) It can burn your nose. It typically dries in under 10 minutes and then the smell dissipates.

While it’s marketed as an all-surface primer, we’ve found it doesn’t bond to fresh plaster, despite what the label claims. It almost always blisters creating more patching, dust, essentially more work. For traditional lime plaster patches, we still rely on oil primers for proper adhesion.

Comparable to: CoverStain. -

PPG SealGrip –

Product Link

Our go to acrylic primer. This is a high build general purpose primer we use when solvent based primers are not ideal. We often use this in conjunction with drywall patches as it aids in the formation of roller stipple. This is a critical step that most of our competition skips, but causes patches to be more pronounced due to the lack of proper texture of the top coat. Paint and primer in one is purely a marketing gimmick! PVA Drywall primer lays out flat. While it has excellent hide, is incredibly cheap, it does not aid in the creation of roller stipple.

Comparable to: ICI/Glidden Gripper, Benjamin Moore Stix

1 of 4

source.

What’s the difference between vinyl, latex, and acrylic paint?

Here's the difference:

We use 100% acrylic paint because it holds up to Buffalo humidity, seasonal movement, and gives our clients years of clean, trouble-free walls and ceilings.

🎨 What’s the Difference?

| Type | Resin Base | Durability | Flexibility | Washability | Common Uses |

|---|---|---|---|---|---|

| Vinyl | Vinyl acrylic | 🟡 Fair | 🔴 Poor | 🔴 Poor | Cheap builder-grade wall paint |

| Latex | Usually vinyl or acrylic-based | 🟡 Good (depends) | 🟡 Okay | 🟡 Good | General wall paint; low VOC interior jobs |

| 100% Acrylic | Acrylic resin | 🟢 Excellent | 🟢 Excellent | 🟢 Excellent | Exterior, ceilings, trim, bathrooms, siding |

Primer >

Drywall & Plaster Repair >

-

USG Mold Tough Drywall –

Product Link

For ceiling and wall repairs, we prefer to use mold and moisture resistant drywall instead of standard gypsum board. While regular drywall works fine under normal conditions, our philosophy is simple: if it leaked once, it could leak again.

Installing moisture resistant drywall helps reduce the risk of future mold growth should another leak occur. It’s a small upfront upgrade that could save homeowners from costly remediation down the line. -

Blue Board / Imperial Board –

Product Link

Used in veneer plaster systems and recently replaced rocklath due to our inability to acquire Rocklath locally. The Imperial board panel has a special paper that allows the direct application of plaster base and finish coats with out compromising the gypsum core . You can not buy this at local big box stores, and can only be acquired through special ordering.Imperial board—commonly referred to as blueboard—is a gypsum-core panel that may look like drywall to the untrained eye, but it’s a completely different product. The key difference lies in the face paper and how the panel handles moisture from plaster putty.

Blueboard is manufactured with a special paper facing and an internal moisture-resistant layer. This waterproof barrier serves two critical purposes during plaster application:

- It prevents premature drying. Standard drywall pulls moisture too quickly from the plaster, which can cause check-cracking due to improper drying. Once check-cracks occur, often the only remedy is to chip off the finish, and do it again.

- It protects the gypsum core from saturation. On standard drywall, excess moisture will soak into the gypsum core, leading to bowing or outright failure of the panel.

In short, blueboard is specifically engineered to receive plaster. Drywall is not.

There are trade-specific workarounds and techniques we’ve developed over years of experience. As well as generational trade secrets. These methods allow us to solve complex issues quickly and easily, but we don’t publish them online for one simple reason: our competitors and content scrapers are watching.

A content scraper is an automated program that scans information-rich websites like ours and rewrites the content to use elsewhere, without permission or context. (Yes, this has happened to us.) We prefer to keep our best techniques in-house to protect the integrity of our work and ensure our clients continue to receive something they can’t find anywhere else. -

Wood-Lath

Wood-lath often just called “lath” consists of 1" tall wood strips nailed horizontally to the interior wall and ceiling framing. In traditional plaster systems, plaster is pushed into the spaces between the lath, creating *plaster keys* which is what holds your walls and ceilings in place. This method held up for centuries and was phased out in the mid-1940s when Rocklath became the new standard. This standard came to be in order to speed up the finishing of homes after World War II and is the precursor to drywall which replaced plaster in the mid 1960's.

If your home has wood lath (homes built before 1950), we won't remove it during repairs. Instead, we fasten metal lath directly over the existing wood lath and apply new basecoat and finish plaster over it. This preserves the original wall structure and allows us to blend the repair more seamlessly. Removing the lath and patching with drywall would leave a perfectly flat, spot—something that would stand out immediately once painted. Plaster walls and ceilings are manually finished by hand. Drywall is made in a factory and is perfectly flat. -

Plaster-Weld –

Product Link

Plaster-Weld is the pink stuff you see in many of our repair photos. It is a bonding agent we use with traditional plaster repair. Despite what some wrongly assume, it doesn’t make plastering easier—it actually makes it more difficult. Once it’s applied and dry, it seals the surface and prevents the suction of the substrate. Most people unknowingly rely on this suction when doing patchwork, expecially on ceilings where your working against gravity.

So why use it? Because when you apply wet plaster over dry Plaster-Weld, the bonding agent reactivates—essentially turning wet again and chemically fusing the new plaster to the existing substrate as it cures. This is critical, because unlike drywall compound (which sticks to everything), plaster typically won't stick anything. This difference in acquiring adhesion is a major reason most people can’t do true plaster work.

Tools & Equipment >

-

Ladders –

We supply all tools and equipment we need to do our job. We have an assortment of step ladders and extension ladders at our disposal in order to reach the work safely and efficiently. We take ladder safety very seriously. As such we will not use your ladders to do our work. -

Scaffolding –

We have three types of scaffolding:

Baby Baker: A small scaffold on wheels which is only used indoors. On larger projects we often use it as a portable workbench.

Baker: A larger scaffold also only used indoors which we use to work on ceilings. considerably smaller than our walkthrough scaffold, but substantially bigger than baby baker.

Walk-through Scaffold: Large steel scaffold often seen on large commercial construction sites. Used both indoors and out, we use this when doing major repairs on tall ceilings. This gives us a 6' x 8' platform to work on. Standard platform height for our walk through is 8' high, so its only used for very high cielings. -

Paint Application –

We brush and roll interior spaces of occupied homes. Our only caveat here are basement ceiling painting - which we spray, and new builds when we will also spray. Otherwise our application is brush and roll.

For exteriors, we will spray on a case by case basis. Everything always gets two full coats of paint. -

Plaster & Drywall Repair –

For our repair work, we use an assortment of specialized tools and equipment that are rarely seen in the broader painting industry. Because our work crosses over from painting into drywall and further into true plaster repair, we rely on tools designed specifically for these highly skilled trades.

From high powered work lights to an assortment of fans, to custom finishing knives, and texturing floats, plaster finishing trowels, our equipment reflects the technical demands of our trade. Most painting contractors don’t own, need, or even recognize many of the tools we use daily. -

Popcorn Ceiling Equipment –

The number of local companies that are capaable of repairing popcorn ceilings is dwindling by the year. It requires a large expensive air compressor, and a texture hopper and a lot of prep for quite literaly 5 minutes of actual work. But the cost of the compressor is the main factor in why many contractors don't bother. You need an auto shop style compressor to do it right. You can not duplicate the texture of a popcorn ceiling using a spray can from a big box store. Please do not do that. We keep everything we need to repair popcorn ceilings on our truck. I have written extensively about our process here.

For popcorn texture removal, we use a 2 gallon garden sprayer and a 6" putty knife.

We select materials not by price, but by how well they perform in real homes. Everything listed here is part of the Carrigan Painting difference.

Project Insights

For some reason some thumbnails wont load..